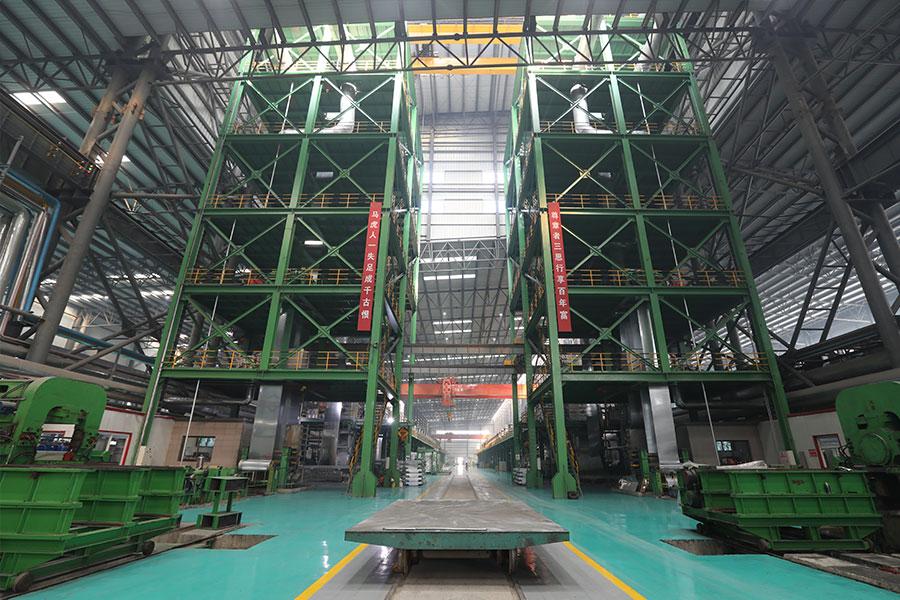

We have introduced four hot galvanized (aluminized) units, all of which are designed with modified Sendzimir process. With excellent online plating thickness control equipment and quality control means of various working procedures, we can ensure the product enjoys excellent plating control accuracy, paintability and weldability. The specific technological process is shown below: Cold-rolled steel strip will undergo direct flame heating and radiation indirect heating-combined modified Sendzimir hot treatment for annealing and restoration after its surface is cleaned and dried through cleaning section, and then enter zinc pot for hot dipping under airtight state; the galvanize steel strip will be obtained on the basis of plating thickness control of air knife and after-plating cooling process. The specific requirement can be met by improving surface quality of plating layer and mechanical property and flatness of steel strip with skin pass mill and tension leveler. After-treatment section can also realize passivating, fingerprint-proof and oiling treatment based as required so as to produce finished galvanized sheet coil. Production scale: With thickness within 0.2 mm-3.0 mm and width within 700 mm-1,250 mm, the product is designed with regular spangle and without spangle plating layer on surface and variety of product includes CQ, DQ, DDQ and HSLA. We are able to manufacture products in accordance with national and international hot galvanized product standards such as ISO, EN, JIS and ASTM, with annual output reaching 1.2 million t, and our products are applicable to building, household appliance, auto, electric appliance, container, traffic, energy and agriculture.

中文

中文