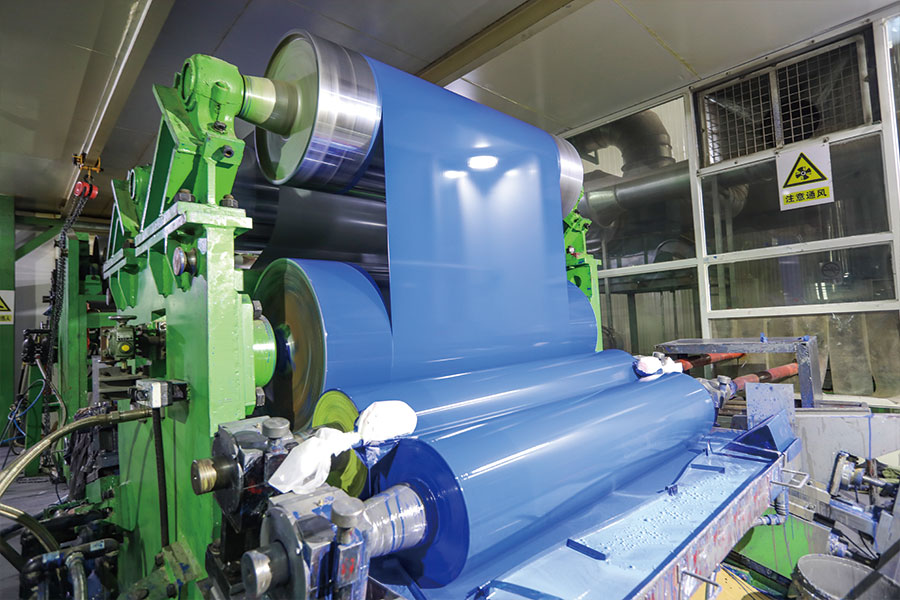

We have established four 150 m/min color-coated high-end automation production lines. In pressure testing of roller, timely adjusted first coat and top coat dual-roller coating head can be designed with dual-coating and dual-drying process. In online thickness testing of primer and finish paint wet film, top coat can be finished by U-type dual-coating head machine. Roller is amounted in online scraper and paint preparation constant temperature system. Protective film laminating machine is installed on online stroboscope examining table. Outlet section is capable of automatic coil separation, threading, taking and discharging. Coiling machine is configured with EPC system, so as to realize aligned coiling of finished steel coil, and coiling helper and seamless coiling block, so as to avoid indentation of finished coil. Coated steel sheet, which is light, beautiful and highly resistant to corrosion and can be directly processed, refers to a brand new raw material for building, shipbuilding, vehicle manufacturing, furniture and electrical industries and has good effect on substitution of steel for wood, high-efficiency construction, energy saving and pollution control. With process speed at 150 m/min, we can produce 120,000 t products on a yearly basis, whose width is within 914~1,250 mm and thickness is within 0.2~1.2 mm.

中文

中文